In this type of fluid bed dryer a vibrating conveyor moves the product through the dryer exposing it to updrafts or air or gas. Vibrating fluid bed dryers use a large drive mechanism with the bed mounted on springs like a vibrating conveyor to move product through the dryer.

Vibratory Fluid Bed Dryers General Kinematics

Vibratory Fluid Bed Dryers General Kinematics

For details please click here.

Vibrating fluidized bed dryer. The flow of particles could be considered as plug-flow which means the vibration intensity in addition to the gas flow are significant factors that affect the drying rate particle mean residence time and particle dispersion 7. Vibrating Fluid Bed Dryer. The main disadvantage is that the dryer and the product are subjected to significant g-forces.

The vibrating fluidized bed dryer is driven by a vibrating motor with stable operation low noise long life and convenient maintenance. Product is moved in the dryer using the micro throwing movement a well-known method in vibration feeding technology that can be individually set up for each application and machine type through the adjustment of swing. Like conventional fluid bed dryers vibrating fluid bed dryers function by passing a process gas directly through a bed of solids via a perforated plate or another type of fluidizing media.

Ø The vibrating fluidized bed dryer is composed of a distribution system an air inlet filtration system a heating and cooling system a host machine a separation and dust removal system a discharge system an exhaust system and a control system. We will work with you to determine the best dryer for your application while considering your. Vibrating fluid bed is a drying process which is carried out on the principle of solid fluidization.

Even though numerous publications and its popularity in industrial applications the knowledge about vibratory. A vibrating Fluid Bed provides optimal processing conditions and transport of products with relatively poor fluidization characteristics. In general the vibrating fluidized bed dryers are used for drying cohesive sticky and agglomerated materials that cannot be well fluidized.

Since the first discovery of vibratory fluidized bed its vibration properties proves to be more efficient in dealing with fine particles which appears to be very difficult to achieve with normal fluidized bed. Material enters the dryer by the feed inlet via the vibration force material is conveyed along the drying zone in a continuous movement. Showcasing the companys signature vertical air flow engineering Witte dryers feature a porous conveying surface set within an enclosed vibrating vessel.

Vibrating fluidized bed dryer referred to as vibrating fluidized bed is a new type of fluidized high-efficiency drying equipment suitable for drying granul. Treated gas is passed through the perforated plate to transfer the energy and liquid. Vibro fluidized bed dryers are highly efficient.

Moisture is removed by evaporation to the surrounding air stream. Witte Vibrating Fluid Bed Dryers offer a series of engineering advances that yield superior drying performance. The VIBRO-FLUIDIZER is most often applied as a final stage in a spray drying process for after drying or cooling but it can also be operated as an individual unit to dry cool de-dust or agglomerate powders from other processes.

Uniquely flexible for a wide range of continuous processing needs GKs vibrating fluid bed dryer for bulk processing is ideally used for heating drying cooling coating or elutriation. Vibrating fluidized bed is under the action of external force so that the solid particles are blown up by the air and suspended in the air for free movement the particles collide with each other mix the height of the material layer rises so that the whole material layer presents a similar fluid form. Industrial dryers from Carrier Vibrating Equipment efficiently and effectively remove moisture from large amounts of nearly any material.

The K-S Vibrating Fluid Bed Dryer VFBD is a fully enclosed design that prevents contamination from outside the environment. Material that has a wide particle size distribution fluid bed dryer vibration will help to discharge oversize particles that will not fluidize. For wet particles or a very thin bed layer.

Hypromellose Vibrating Fluid Bed Dryer Hypromellose Vibration Fluid Bed Dryer Find Details about Fluid Bed Dryer Fluid Bed Dry Machine from Hypromellose Vibrating Fluid Bed Dryer Hypromellose Vibration Fluid Bed Dryer - Changzhou Welldone Machinery Technology Co Ltd. Welcome to STARKAIRE manufacturer of Frac Sand Fluid Bed Dryer Systems for over 40 Years. Our dedicated team will work with you to design machinery tailored to the type and quantity of material you need dried.

Ø When working the material is added to the drying room of the vibrating fluidized bed dryer by the distributor and the material meets the hot air and cold air in the. The FLUID BED SYSTEM dries and cools industrial minerals and chemicals by lifting and supporting a bed of particulate solids on upward flowing gas directed to the mass of material through an air distribution grid. Vibratory Fluidized Bed VFB is a type of fluidized bed where the mechanical vibration enhances the performance of fluidization process.

Vibration is added to aid in fluidization of more difficult materials. The vibration of the vibrating fluidized bed dryer makes the material easy to reach the fluidized state which increases the effective heat transfer coefficient so. Via direct heat transfer so the heat transfer medium comes directly into contact with the product.

GK vibrating fluid beds are available in a variety of configurations and utilize vibratory agitation while passing a process gas through the material bed to. This proprietary technology directs heat transfer air or gas to pass up vertically through the product creating the high degree of fluidization that promotes maximum air. JÖST vibrating fluid bed dryers for bulk materials use convection to transfer the heat energy required for drying ie.

It is through this air or gas that the sugar is brought into a liquid state causing high heat transfer that is enhanced by the vibrating motions. Vibrating fluid bed dryers are well suited for.

Vibrating Fluidized Bed Dryer 11 Download Scientific Diagram

Vibrating Fluidized Bed Dryers And Coolers Kinergy

Vibrating Fluidized Bed Dryers And Coolers Kinergy

Vibrating Fluid Bed Dryers And Coolers 2020 02 24 Process Heating

Vibrating Fluid Bed Dryers And Coolers 2020 02 24 Process Heating

Vibrating Fluid Bed Dryer Archives Oli Vibrators

Vibrating Fluid Bed Dryer Archives Oli Vibrators

Witte Vibrating Fluid Bed Dryer Yields Superior Drying Performancewitte

Vibrating Fluid Bed Dryer Komline Sanderson

Vibrating Fluid Bed Dryer Komline Sanderson

Vibrating Fluidized Bed Dryer For Salt Grain Sugar Pellet Granule Seasoning Tea Seed China Salt Dryer Fluidized Bed Dryer Made In China Com

Vibrating Fluidized Bed Dryer For Salt Grain Sugar Pellet Granule Seasoning Tea Seed China Salt Dryer Fluidized Bed Dryer Made In China Com

Zdg Series Vibration Fluidized Bed Dryer Jiangsu Yutong Drying Engineering Co Ltd

Fluid Bed Dryer Design Allows Complete Cleaning To Prevent Cross Contamination Minimize Risk Of Allergen Transfer And Speed Changeover Wittewitte

Fluid Bed Drying Myths And Misconceptions Clearing The Airstreamwitte

Vibrating Fluid Bed Dryers Coolers Vibra Maschinenfabrik Schultheis Gmbh

Chemical Industry Vibrating Fluidized Bed Dryer Barium Sulfate Potassium Nitrate

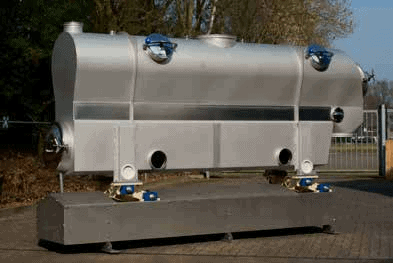

Vibrating Fluid Bed Dryers Design And Manufacturing Tema Process

Vibrating Fluid Bed Dryers Design And Manufacturing Tema Process

Vibrating Fluid Bed Dryer China Drying Machine Manufacturer

Vibrating Fluid Bed Dryer Kilburn

Vibrating Fluid Bed Dryer Lemar

Witte Vibrating Fluid Bed Dryer Yields Superior Drying Performancewitte

Vibrating Fluid Bed Dryers Replace Belt Dryers For Food Processwitte

0 Response to "Vibrating Fluidized Bed Dryer"

Posting Komentar